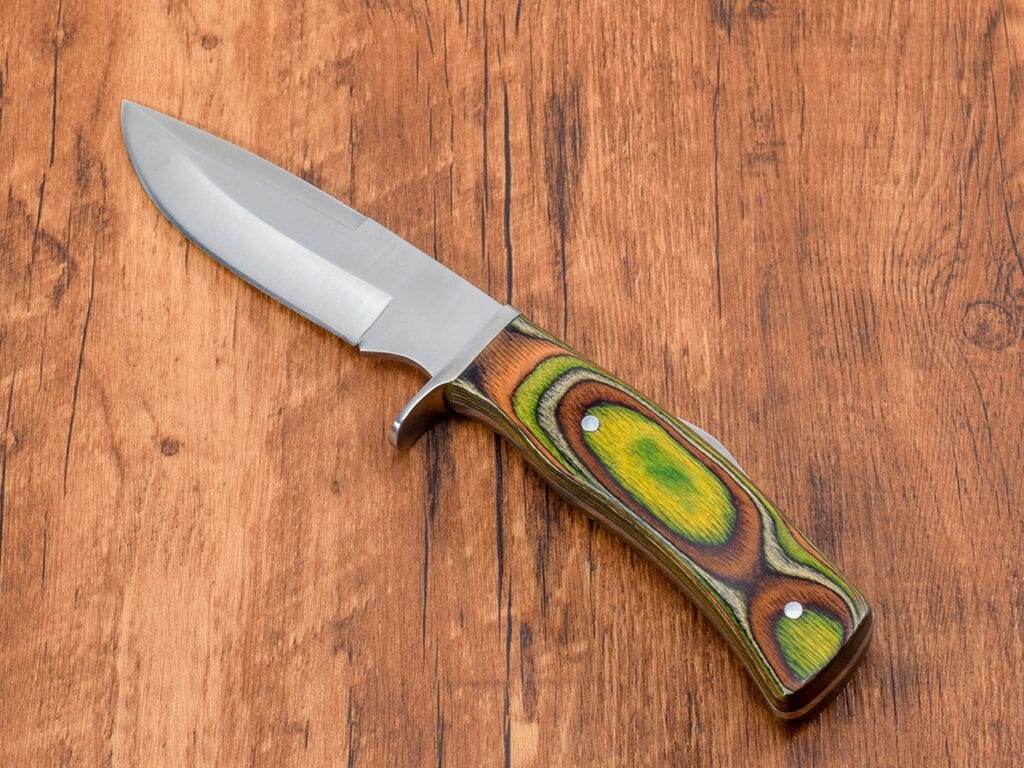

Are you curious about 3CR13 stainless steel and its performance in knives? This comprehensive guide will walk you through everything you need to know about this popular Chinese steel, from its composition to real-world performance. Whether you’re a knife enthusiast or just researching your next purchase, this article will help you understand if 3CR13 steel is the right choice for your needs.

What Is 3CR13 Stainless Steel?

3CR13 is a Chinese martensitic stainless steel commonly used in budget-friendly knives. This type of steel belongs to the 400 series stainless steel family and is often compared to 420 steel in terms of its properties and performance. As a martensitic stainless steel, it offers a good balance between hardness and corrosion resistance, making it suitable for various knife applications.

What Are the Key Properties of 3CR13 Steel?

The properties of 3CR13 stainless steel make it an interesting choice for knife makers. Here are the main characteristics:

- Moderate hardness (52-55 HRC after heat treatment)

- Good corrosion resistance

- Decent edge retention

- Easy to sharpen

- Excellent toughness

- Affordable price point

How Does 3CR13 Compare to Other Knife Steels?

When comparing 3CR13 to other popular knife steels, it’s important to consider its position in the market. This steel is often found in budget-friendly pocket knives and is comparable to:

- 420 Steel: Similar corrosion resistance but slightly better edge retention

- 440C: Lower performance but more affordable

- 8Cr13MoV: Slightly lower overall performance but similar price point

What Is the Chemical Composition of 3CR13?

The chemical composition of 3CR13 steel includes:

| Element | Percentage |

|---|---|

| Carbon | 0.24-0.40% |

| Chromium | 12-14% |

| Silicon | ≤1.0% |

| Manganese | ≤1.0% |

| Phosphorus | ≤0.04% |

| Sulfur | ≤0.03% |

How Does Heat Treatment Affect 3CR13 Steel?

Heat treatment plays a crucial role in determining the final properties of 3CR13 steel. The process typically involves:

- Preheating to 1500°F

- Austenitizing at 1850°F

- Quenching in oil or air

- Tempering between 300-700°F

What Are the Advantages of Using 3CR13 Steel in Knives?

3CR13 stainless steel offers several benefits for knife manufacturers and users:

- Cost-effective manufacturing

- Good machinability

- Decent corrosion resistance

- Easy maintenance

- Suitable for everyday use

What Are the Limitations of 3CR13 Steel?

Understanding the limitations of 3CR13 steel is important for making an informed decision:

- Moderate edge retention compared to premium steels

- Limited wear resistance

- Not ideal for heavy-duty tasks

- May require more frequent sharpening

Is 3CR13 Good for Kitchen Knives?

3CR13 steel can be suitable for kitchen knives, particularly in budget-friendly options. Its properties make it:

- Resistant to kitchen chemicals and moisture

- Easy to maintain and sharpen

- Durable enough for regular kitchen tasks

- Affordable for home cooks

How to Maintain a 3CR13 Steel Knife?

Proper maintenance of your 3CR13 steel knife includes:

- Regular cleaning after use

- Keeping the blade dry

- Periodic sharpening

- Applying light oil for storage

- Avoiding harsh chemicals

Who Should Consider a 3CR13 Steel Knife?

3CR13 stainless steel knives are particularly suitable for:

- Budget-conscious buyers

- Beginners in knife collecting

- Light to medium duty use

- Those who don’t mind regular maintenance

- Casual everyday carry users

Key Takeaways:

• 3CR13 is a budget-friendly stainless steel with good overall performance • Offers decent corrosion resistance and edge retention • Easy to maintain and sharpen • Suitable for everyday use and light tasks • Best for those seeking value for money • Requires regular maintenance for optimal performanceRemember, while 3CR13 may not compete with premium steels, it offers reliable performance at an affordable price point, making it a practical choice for many users.