Are you interested in adding a personal touch or brand identity to your custom knives? Laser logo engraving on knife blades has become increasingly popular for both manufacturers and enthusiasts. This comprehensive guide will walk you through everything you need to know about the process, from choosing the right equipment to achieving perfect results.

What is Laser Engraving and Why Choose it for Knife Blades?

Laser engraving is the process of using concentrated light beams to mark or etch designs into knife blades. This modern technique offers several advantages:

- Precise and consistent results

- Permanent marking that won’t fade

- Ability to create intricate designs

- No physical contact with the blade surface

- Minimal material removal

How Does Fiber Laser Engraving Work on Metal Blades?

The fiber laser engraving process uses high-powered laser beams to mark stainless steel blade surfaces. During operation, the laser creates microscopic changes in the metal surface, resulting in permanent markings.The process involves:

- Concentrated laser beam application

- Controlled heat application

- Surface modification at the molecular level

- Precise depth control

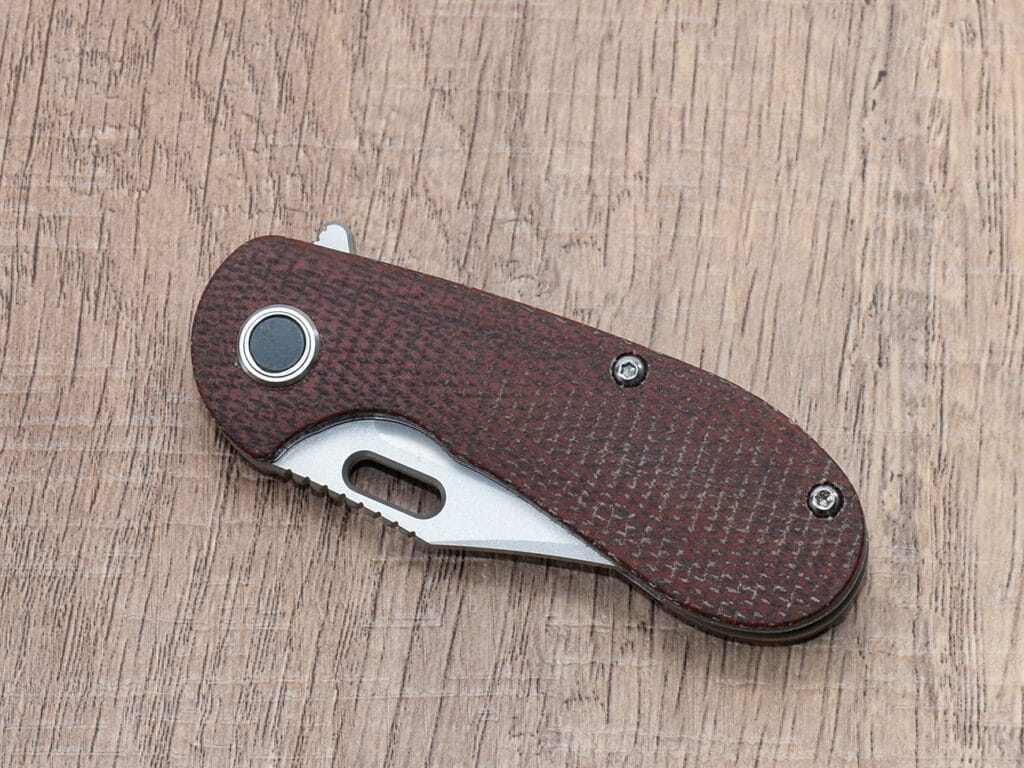

Unable to render image

What Equipment Do You Need for Laser Engraving Knives?

To properly engrave knife blades, you’ll need:

- Fiber laser engraver (20W-60W recommended)

- Computer with design software

- Proper ventilation system

- Safety equipment

- Blade holding fixtures

Which Knife Materials Work Best with Laser Engraving?

Different blade materials respond differently to laser engraving. Here’s a breakdown:

| Material | Engraving Quality | Recommended Power |

|---|---|---|

| Stainless Steel | Excellent | 30W-60W |

| Damascus Steel | Good | 40W-60W |

| Carbon Steel | Very Good | 30W-50W |

| Titanium | Excellent | 20W-40W |

How to Prepare Your Knife for Laser Engraving?

Proper preparation is crucial for successful engraving:

- Clean the blade thoroughly

- Remove any oils or residues

- Mark the engraving area

- Secure the blade properly

- Test settings on similar material

What Are the Best Design Practices for Knife Logos?

Creating effective designs for custom knife engraving requires careful consideration:

- Keep designs simple yet distinctive

- Consider blade curvature

- Maintain appropriate size ratios

- Use vector-based artwork

- Test designs before final engraving

How to Achieve the Perfect Engraving Depth?

Controlling engraving depth is crucial for maintaining blade integrity:

“The ideal engraving depth should be between 0.001″ and 0.003″ for most applications. Deeper engravings can potentially affect blade strength.”

What Safety Measures Should You Follow?

Safety is paramount when laser engraving knives:

- Wear appropriate eye protection

- Ensure proper ventilation

- Use appropriate fixtures

- Follow manufacturer guidelines

- Maintain clean work area

Common Problems and How to Solve Them

Here are solutions to frequent issues:

- Unclear Markings

- Adjust laser power

- Clean surface thoroughly

- Check focus distance

- Inconsistent Depth

- Verify material flatness

- Check fixture stability

- Adjust speed settings

How to Care for Laser Engraved Knives?

Proper maintenance ensures longevity of your engraved pocket knives:

- Clean gently with mild soap

- Avoid abrasive materials

- Apply protective coating if needed

- Store properly

- Regular inspection

Key Takeaways:

- Choose appropriate laser power for your blade material

- Proper preparation is essential for quality results

- Safety should always be your top priority

- Regular maintenance ensures engraving longevity

- Professional equipment yields best results

- Testing is crucial before final engraving

Remember these points to achieve professional-quality laser engraving on your knife blades. Whether you’re a manufacturer or enthusiast, these guidelines will help you create beautiful, lasting marks on your knives.